Description

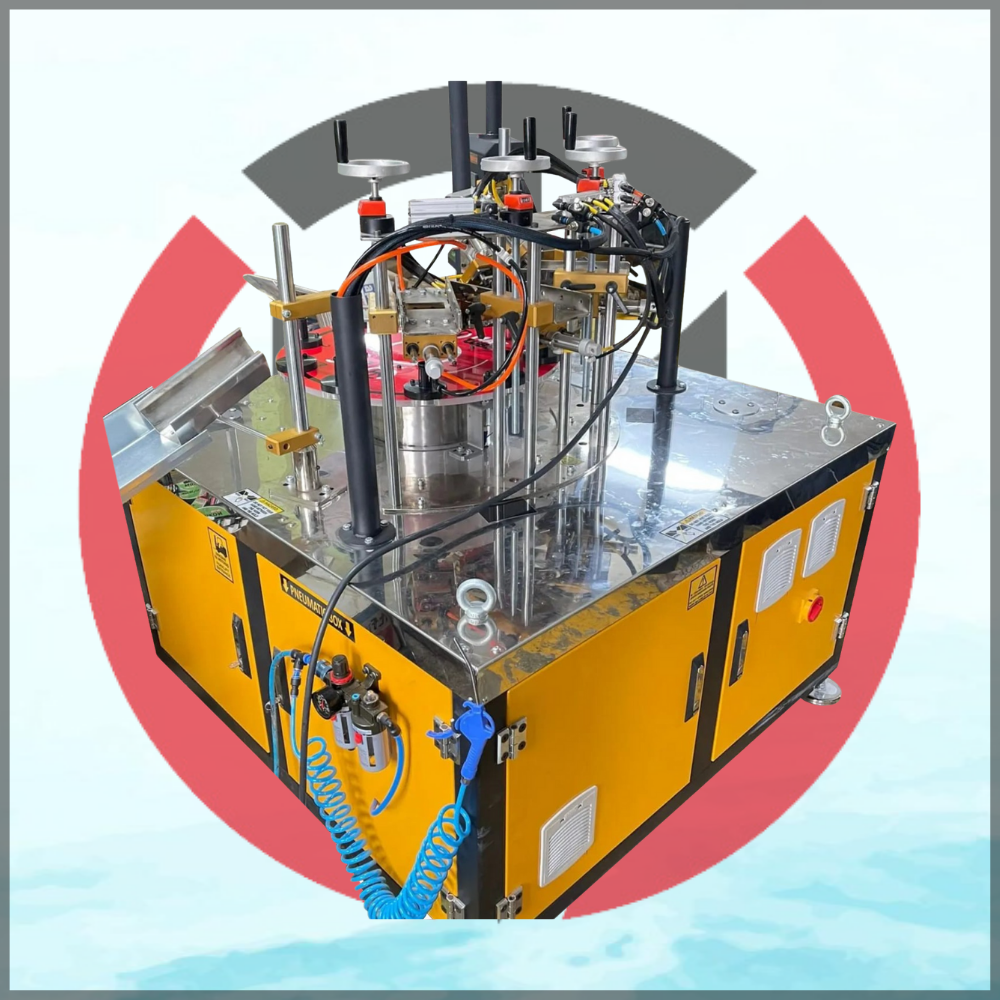

* The product filling section of the machine is made of 316 quality stainless steel.

* The minimum diameter of the tube to be produced is 22 mm – maximum 50 mm.

* The volume of the filling unit is min. 10 ml – max. 300 ml.

* The machine is adjustable according to the length and diameter of the tubes to be filled.

* The tube filling capacity of the machine is 30-35 min/piece.

* The filling unit works with volume filling logic, the mouth of the filling nozzle unit closes pneumatically.

* Nozzle air blowing technology cuts the bearding after filling.

* Easy adjustment with the flywheel arm and indicator technology in the stations

* Horn cracking failures are prevented with the new generation horn technology.

* The new generation actuator system is easy to clean and install, faster and wear problem is prevented.

* The filling station is servo controlled and weight adjustment and speeds are provided on the screen.

* New generation clamp system tube molds (old pin systems have been removed due to rust and corrosion).

* The cutting station is designed as a double blade and measures have been taken against dulling.

* The numbering date coding jaw is designed to be easily removable and there will be no jamming in the numbers.

* With the on-screen recipe system, settings can be saved with 200 recipes.

* Since the tube lengths are +-30mm long or short, instead of buying new molds, the setting positions at the stations have been increased.

* The parts where the product passes and comes into contact are 316 quality stainless steel and are mirror-polished.

* The chassis assembly is steel extruded profile and specially oven-painted.

* The machine’s feeder set is provided free of charge for diameters of 19 and 50.

* The machine consumes 250 liters of air per minute.

* The machine has a 10 inch touch “touch screen” control panel and “plc” control.

* The machine has the ability to connect the plc and operator panel via the internet and to intervene and send programs. There is a Windows based operating system on the PLC panel.

* BANNER brand sensor is used as the product rotation control sensor.* Pneumatic equipment used in the machine is PEMAKS and BOSCH RexRot brand and

is of GERMAN origin.

* Product point introduction can be easily made via the operator panel.

* Pneumatic piston sensors are SICK brand and GERMAN origin sensor is used.

* The rotary table has 10 stations and is safe against product jamming and operator hand jamming.

* Weight 850 kg

* 380 Volt

MACHINE OPTIONAL FEATURES:

* Automatic tube feeding unit

* Wallless and liquid level hopper

* Numbering channel mold and 55 numbering devices that can print DAY-MONTH-YEAR.

* 2 sets (10 pieces) of antibacterial imported PVC molds according to the desired tube.

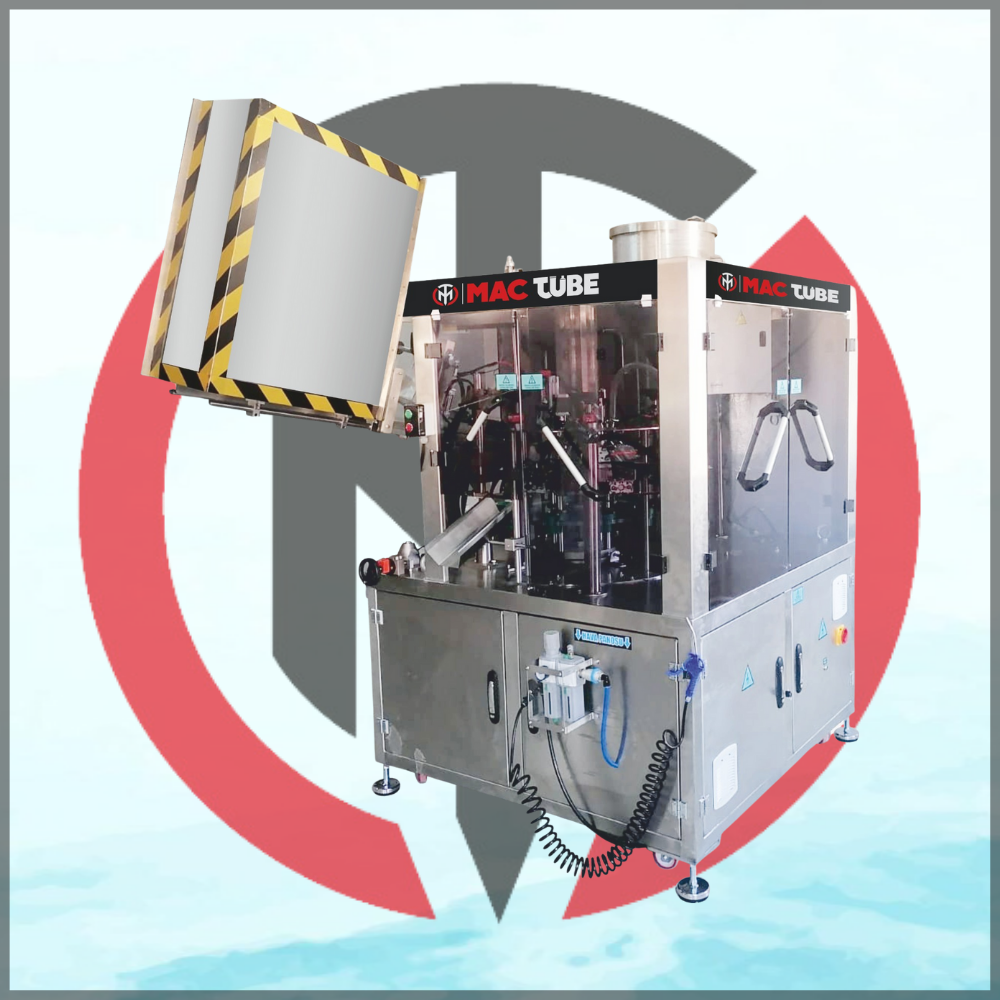

* Specially designed cabin and Door Safety Switch

WARRANTY PERIOD AND AFTER SALES SUPPORT

* The machine produced by the contractor has a 2-year mechanical

1-year electronic

warranty against manufacturing and assembly errors.

* The repair period that MACTUBE TUBE FILLING AND

PACKAGING MAK SAN.TİC.LTD.ŞTİ

will be added to the warranty period.